Originally, sticks were used to hit the ball when playing baseball. But as the game developed, players started to use wood bats which they carve on their own or buy from a shop.

A lot of experimentation regarding the size and shape of the baseball bats was made since there is no regulation yet on the bat structure. Because of this, rules had to be established.

You can’t use any self-created bat or a bat with the wrong dimensions anymore. Baseball players need high-quality branded bats that are 100% accurate, meet BBCOR standards, and follow the guidelines of the baseball leagues.

Now, several questions arise,

How do the manufacturers make baseball bats today?

What are the processes that occur in producing an aluminum bat and a wood bat?

And other similar questions.

So, here, I’ll try to answer every question that comes to your mind related to the manufacturing of wood and aluminum bats.

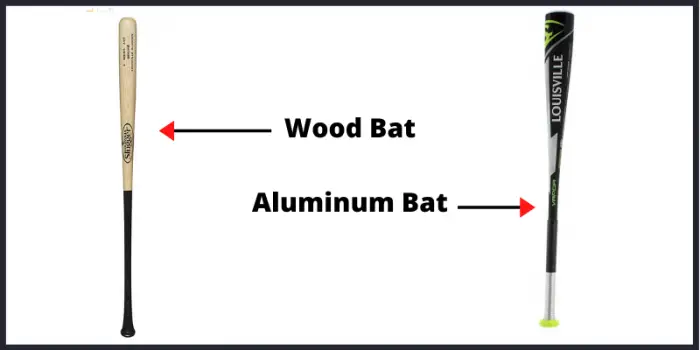

Types of Baseball Bats

Before we start learning about the process of making a bat, it’s important to learn about the two common types of bats.

- Wood Bats

- Aluminum Bats

The aluminum bats can be used in the little leagues and youth leagues. These bats are lightweight and provide an advantage to the hitter. Wood bats can also be used in the little or youth leagues, depending upon the preference of the player.

While, in the major or professional leagues, only wood bats are allowed because it is believed that the professional players have enough strength & skills that they don’t require any additional benefit from the bat.

How are Baseball Bats Made?

How are Wood Bats Made?

The process of making a wooden bat is different from the making of an aluminum bat.

It is also important to know about the different types of wood that can be used to make a bat. But, while manufacturing a single bat, only one type of wood is used.

You must be thinking,

Which wood can be used to make a baseball bat?

Baseball bats can be made from any of the six different types of wood.

The six different types of wood that are allowed by Major League Baseball are:

The majority of the bats are made of either Sugar Maple or White Ashwood.

The Process of Making a Wooden Baseball Bat

First, the wood is placed in the modern lathe which makes it a cylindrical shape.

The weight is checked, and after that, it is again placed on the modern lathe machine that gives it a rough baseball bat shape.

One of the modern lathe machines takes approximately 3 minutes to give the raw wood a rough shape of a bat. The time it takes depends on the lathe machine, and it can be less or more depending upon the lathe machine.

Now, the final shape is given manually by removing the extra wood by using a chisel to give an accurate length, weight, and drop weight to the baseball bat.

After that, the final bat is almost ready.

Before painting the bat, the electric sander is used to remove any rough edges that give it a more clean look which is necessary.

The final weight is again checked, whether it meets the standard size & weight as per the player’s requirement or not.

After painting the bat, the brand name, model number, and other things are applied to the bat.

This is the final step that completes the process of making a baseball bat.

How are Aluminium Bats Made?

The process of making an aluminum bat starts with the cutting of aluminum rods into similar size as bats.

These aluminum rods are loaded in the computerized lathe and cut the inner part of the rod is. This makes it hollow from the center.

Now, these small aluminum rods are stretched up to twice their length.

By using a forming tool, these aluminum rods were given a rough shape of an aluminum bat.

The manual check is done to see whether the bat is straight. If it’s not, then by applying hydraulic pressure to bend it into the shape.

This is a very important step as a non-straight bat can hugely affect the performance of a player.

Next, an electric sander is used to get rid of any rough surfaces and any small defects.

Heavy-duty paint is used on the bat because they are used a lot in the game with numerous hitting.

The trademark, model number & name are applied to the bat along with the finishing of the bat.

The aluminum knob is fused with the handle by welding, and the plastic end cap is pressed at the end of the bat.

To provide a non-slip grip on the handle, synthetic leather, lizard skin grip, or any other grip is wrapped around the handle.

Finally, the process of manufacturing an aluminum bat is finally done.

Wooden vs. Aluminum Baseball Bats: Which Is the Better Option?

When it comes to choosing a baseball bat, there are two main types to consider: wooden and aluminum. While some players swear by the traditional wooden bats, others prefer the newer aluminum ones. Let’s take a closer look at the pros and cons of each option to determine which is the better choice.

Pros and Cons of Wooden Bats:

Pros and Cons of Aluminum Bats:

Some Common FAQs about Making Baseball Bat

-

What are the two common types of baseball bats?

The two common types of baseball bats are wood bats and aluminum bats.

-

What types of wood can be used to make a baseball bat?

Baseball bats can be made from any of the six different types of wood, including Sugar Maple, White Ashwood, Yellow Birch, Red Oak, Hickory, and Bamboo.

-

How are wood baseball bats made?

Wood baseball bats are made by placing wood in a modern lathe machine, shaping the wood into a rough baseball bat shape, manually removing extra wood to give an accurate length, weight, and drop weight, sanding the rough edges, painting the bat, and applying the brand name and other details.

-

How are aluminum baseball bats made?

Aluminum baseball bats are made by cutting aluminum rods into similar sizes as bats, loading the aluminum rods in a computerized lathe machine, making the rods hollow, and stretching the aluminum rods up to twice their length, giving them a rough shape of an aluminum bat, straightening the bat, sanding it, painting it, applying for the trademark, model number and name, fusing the aluminum knob with the handle by welding, and pressing a plastic end cap at the end of the bat.

-

Which is better, wooden or aluminum baseball bats?

When it comes to choosing a baseball bat, there are pros and cons to both wooden and aluminum bats. While wooden bats are heavier and provide a traditional feel, aluminum bats are lighter and provide an advantage to the hitter. However, in the professional leagues, only wood bats are allowed because it is believed that professional players have enough strength and skills that they don’t require any additional benefits from the bat. Ultimately, the choice of a bat depends on the personal preference of the player.

-

What are BBCOR standards?

BBCOR stands for “Batted Ball Coefficient of Restitution”. It is a certification that baseball bats need to pass to be considered legal to play in high school and college. BBCOR standards ensure that the ball does not come off the bat too fast, making the game safer for players.

-

What is the difference between aluminum and wooden bats?

The primary difference between aluminum and wooden bats is their construction. Aluminum bats are hollow and made of metal, while wooden bats are solid and made of wood. Aluminum bats are generally lighter and provide an advantage to the hitter, while wooden bats require more skill and strength to use effectively.

-

Can aluminum bats be used in professional baseball?

No, in professional baseball, only wooden bats are allowed. This is because professional players are believed to have enough strength and skill to hit the ball without any additional advantage from the bat. However, aluminum bats can be used in little leagues and youth leagues.

Final Thoughts

The above-mentioned steps are used by all the bat manufacturers, but there can be some minor changes from one company to another depending upon whether they’re making a BBCOR bat for power hitters or drop 10 USA bat.

Some companies use white ash while others use maple wood for making wood bats because these two are the widely used woods in manufacturing.

If you have any questions regarding the manufacturing of baseball bats, then feel free to put them in the comment box.